In today’s world of advanced healthcare, 3D printing is revolutionising how medical devices are designed and manufactured. This cutting-edge technology is enabling the production of highly customised and cost-effective medical tools and devices, transforming patient care and improving healthcare outcomes. For a diverse market like India, where accessibility and affordability are often key concerns, 3D printing presents immense potential to address these challenges and create innovative solutions tailored to local needs.

A Closer Look at 3D Printing in Medical Devices

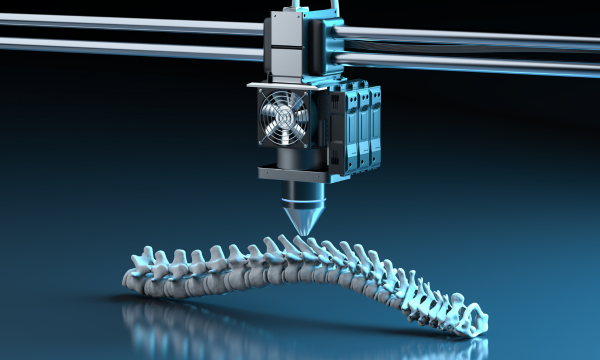

At its core, 3D printing, or additive manufacturing, involves building objects layer by layer from a digital blueprint. This technique differs from traditional manufacturing, which typically involves cutting or moulding materials. When it comes to medical devices, 3D printing allows for unparalleled precision and flexibility, making it possible to create devices specifically designed for individual patients or unique medical situations.

For instance, consider the creation of a prosthetic limb. Using 3D printing, a prosthetic can be designed to fit the exact dimensions of a patient, ensuring comfort and functionality. The level of customisation and accuracy achieved with this technology is unmatched, offering a glimpse into the future of personalised medicine.

Applications of 3D Printing in the Healthcare Sector

The versatility of 3D printing technology is evident in its wide range of applications within the medical field. It is used to produce everything from customised implants and prosthetics to surgical instruments and training models. For example, anatomical models created through 3D printing help surgeons plan complex procedures with greater accuracy, reducing risks and improving surgical outcomes.

In addition to traditional applications, researchers are exploring the use of 3D printing in bioprinting, a process that creates biological tissues and organs. While still in its infancy, this innovation has the potential to address critical shortages in organ donation and transplantation. Moreover, the technology is helping address affordability concerns by enabling the production of cost-effective medical devices for underserved regions.

The Advantages of 3D Printing

One of the most significant advantages of 3D printing is the level of customisation it offers. Unlike conventional manufacturing, which focuses on mass production, 3D printing excels at creating personalised solutions tailored to specific needs. This is especially critical in medical applications, where the fit and functionality of devices can directly impact a patient’s quality of life.

Beyond customisation, the technology is also cost-efficient. By reducing material waste and eliminating the need for expensive moulds, 3D printing makes the production process more affordable. This is particularly beneficial for a market like India, where the cost of healthcare often poses a barrier to access. Furthermore, the ability to rapidly prototype devices speeds up innovation, enabling manufacturers to bring new products to market faster than ever before.

Challenges in Implementation

Despite its many benefits, the widespread adoption of 3D printing in the medical devices industry is not without challenges. Regulatory compliance remains a major hurdle, as authorities must ensure that 3D-printed devices meet strict safety and quality standards. This can complicate the approval process, particularly for innovative products that don’t fit within traditional regulatory frameworks.

Additionally, the cost of setting up a 3D printing facility can be high, requiring significant investment in equipment and training. While the long-term benefits often outweigh these costs, small and medium enterprises may find it challenging to adopt this technology. There are also limitations in the materials available for 3D printing, particularly those that meet the stringent requirements of medical applications.

The Future of 3D Printing in Medical Devices

Looking ahead, 3D printing is poised to play an even more prominent role in the medical device industry. Advances in bioprinting are opening doors to the creation of functional tissues and organs, which could revolutionise transplant medicine. Furthermore, the integration of artificial intelligence (AI) with 3D printing promises to enhance design processes, allowing for the creation of even more innovative and effective devices.

India, in particular, stands to benefit from these advancements. With a strong focus on innovation and affordability, the country is well-positioned to become a global hub for 3D-printed medical devices. Government initiatives such as Make in India and increasing investment in healthcare technology are likely to further accelerate this growth.

Conclusion

The introduction of 3D printing into the medical devices sector marks a transformative shift in how healthcare solutions are developed and delivered. By enabling greater customisation, reducing costs, and fostering innovation, this technology is paving the way for a more efficient and accessible healthcare system.

For manufacturers, healthcare providers, and policymakers, understanding and embracing the potential of 3D printing is essential to staying ahead in this rapidly evolving field. As this technology continues to advance, it holds the promise of transforming not just medical devices but the entire healthcare landscape.